Application of YQ series gas spring

YQ series gas springs are widely used in automobiles, furniture, computers, fitness equipment, textiles, printing, food, tobacco, Benjiang and other machinery, and can play a role in lifting, pausing, closing and other functions. The product structure is reasonable and easy to install and maintain. No external power is required during work, saving energy. The lifting force remains relatively constant throughout the entire work process. The travel terminal has a buffering mechanism to avoid damage to components. The lifting component can be stopped at any position.

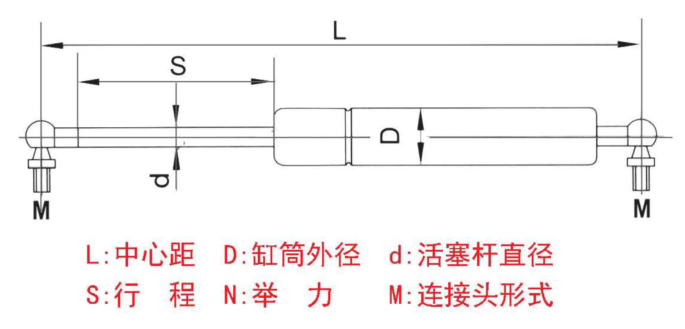

KD series gas spring size and parameter range

| Model | Piston Rod Diameter | Cylinder Outer Diameter | Installment Center Distance | Travel Range | Range Of Lifting Force |

| KD13 | Φ6 | Φ15 | 100-550 | 50-200 | 5-35 |

| KD16 | Φ8 | Φ18 | 210-580 | 50-220 | 15-50 |

| KD20A | Φ10 | Φ22 | 300-700 | 100-300 | 30-80 |

| KD20B | Φ12 | Φ22 | 400-700 | 100-300 | 40-100 |

| KD25A | Φ12 | Φ27 | 600-800 | 220-350 | 60-130 |

| KD25B | Φ14 | Φ28 | 600-900 | 220-350 | 100-300 |

| KD25C | Φ16 | Φ28 | 600-1200 | 220-900 | 100-300 |

Note: The above are partial specifications, and special specifications and purposes can be customized according to user requirements.

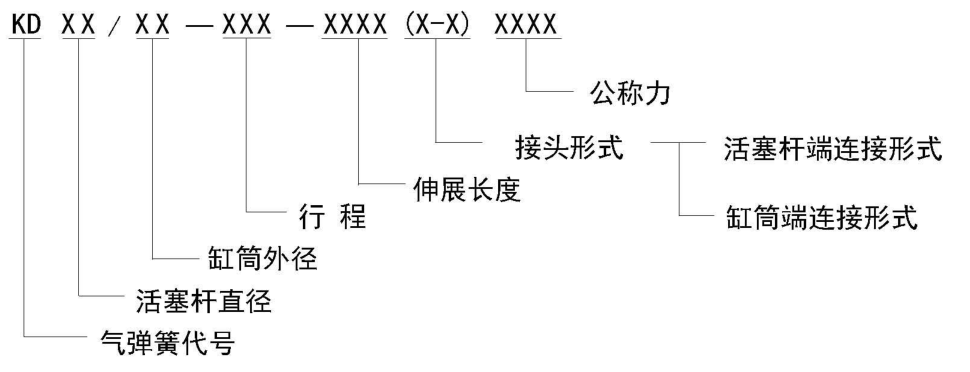

Marking of gas springs and selection of force values

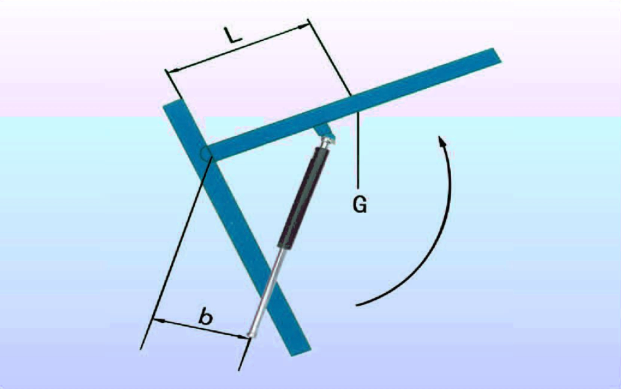

(F1- minimum stretching force, unit: N; G supports gravity in one fell swoop, with the unit of N; L is the distance from the center of gravity to the center of rotation, measured in millimeters; When the gas spring arm is extended, the effective force arm is measured in millimeters; N - Number of gas springs; K - Safety factor, generally K=1.1, can also be determined through negotiation between the supply and demand sides

The marking of gas springs consists of code, piston rod diameter, stroke, extension length, joint form, and nominal force.

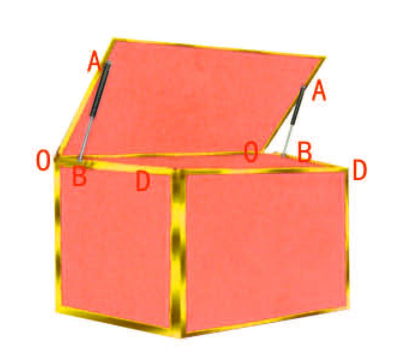

Selection of installation position for gas spring

There are two installation methods to choose from: 1. A0 point is less than the length of OB point; The length of 2.0 V AO* First, determine A Point B, calculate the approximate stroke of the gas spring used: subtract the AB length after opening the box cover from the AB length after closing, which is equal to the required stroke of the gas spring* Recalculate whether the selected gas spring is reasonable: gas spring stroke x 2+80mm - AB length after opening. Note: If the obtained result is greater than AB length, then point A needs to be moved towards point 0 or point B needs to be moved towards point 0 to increase the length of point AB, that is, to increase the length of the gas spring.